MULTI AXIS STAGES

PRODUCT OVERVIEW

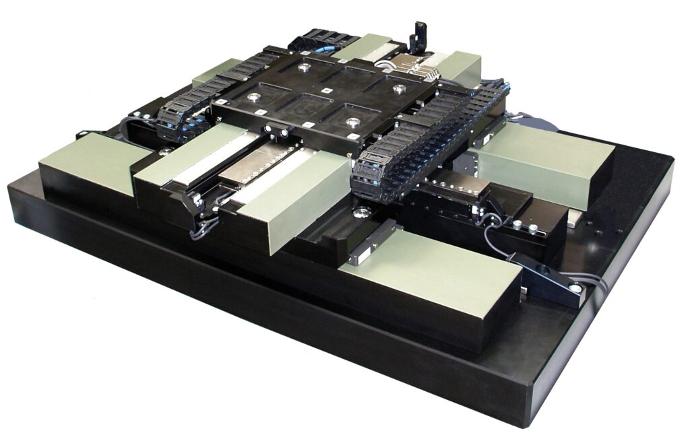

Multi axis motion stages are featured by crossed XY axes with direct drive linear motors .

They are the result of a complex design study including detailed FEM analysis which provides the perfect solution for high precision and dynamic performances. FEM analysis also provides a structural layout able to manage the temperature behavior.

The perfect coupling with flat air bearings and a magnetic preloaded device gives life to a very stiff guide system.

Our multi axis stages adopt ironless linear motors that ensure cogging-free motion and a high performance optical encoder assuring high accuracy feedback results . We count among these top-quality products the MAX XY MOTION SYSTEM and our PLANAR MOTION SYSTEM.

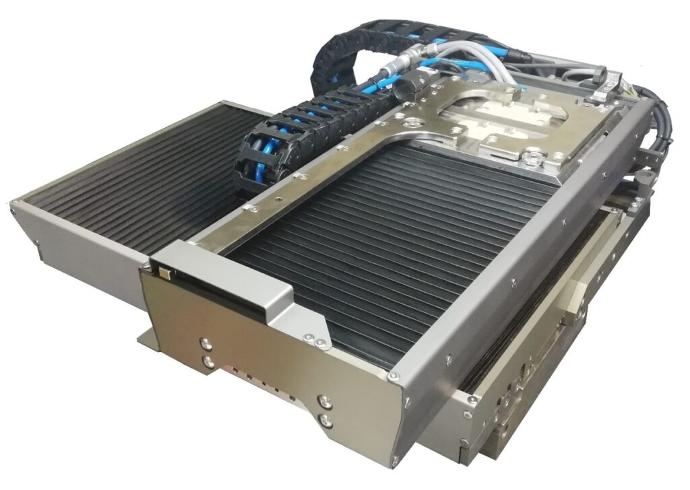

Besides, we have also XY MOTION SOLUTIONS WITH IRONCORE LINEAR MOTORS able to guarantee the highest dynamic performances in a small footprint. These stages are completely manutactured in stainless steel which provides high resistance and a low thermal expansion coefficient .

BENEFITS

Our multi axis motion stages provide customers with benefits as:

- no friction in the guide system

- no stick slip effect

- no vibrations

- no sensitivity to temperature changes

- suitability for a wide range of applications

- no wear and top performance over time

They are perfect to achieve highest demands in precision motion and positioning in:

- optical inspection machines in OPTICS AND MEASUREMENT

- laser micromachining in MICROMACHINING WITH TOOLS AND LASER

- wafer handling processes in ELECTRONICS&SEMICONDUCTOR

- inspection and test in ELECTRONICS&SEMICONDUCTOR.