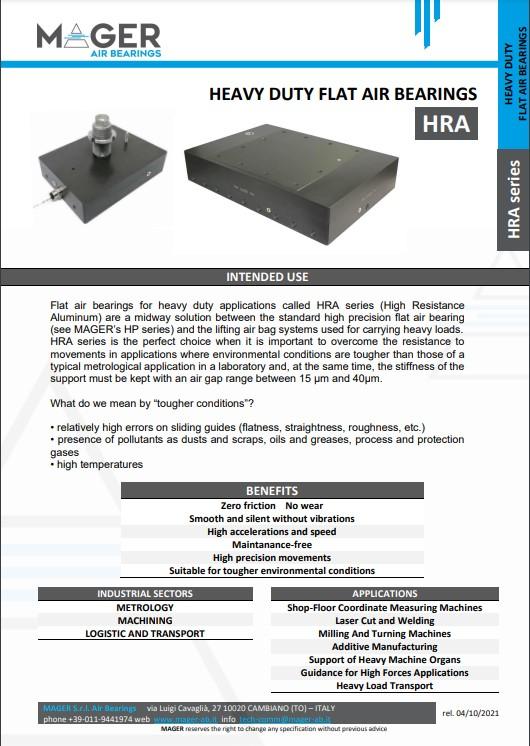

HEAVY DUTY FLAT AIR BEARINGS – HRA series

PRODUCT OVERVIEW

Flat air bearings for heavy duty applications HRA series (High Resistance Aluminum) are a midway solution between the standard high precision flat air bearing (see MAGER’s HP series ) and the lifting air bag systems used for carrying heavy loads.

HRA series is the perfect choice when it is important to overcome the resistance to movement in applications where environmental conditions are tougher than those of a typical metrological application in a laboratory and, at the same time, the stiffness of the support must be kept with air gap range between 15 µm and 40µm.

What do we mean by “tougher conditions”?

- relatively high errors on sliding guides (flatness, straightness, roughness, etc.)

- presence of pollutants as dusts and scraps, oils and greases, process and protection gases

- high temperatures

HRA series is equipped with integrated air gap sensor nozzles

The HRA air bearings series are available:

-

with two methods of

interfacing

:

- with stationary assembly

- with mounting kit ( P-KIT )

-

with two kinds of

coatings for the aerostatic surface

:

- standard coating with hard anodize coating

- coating with anti-seizure material

- with or without wipers ( R-KIT ) perfect for keeping guideways clean of dust, oil, etc .

BENEFITS OF MAGER FLAT AIR BEARINGS

ZERO FRICTION

smooth, ultra-high resolution and high precision movements

high precision measures and machining

state-of-the-art performances of the machine

NO-CONTACT

no wear

high dynamics, performance preservation, free-maintanance systems

lower costs and higher productivity

GAS LUBRICATION

NO grease or oil

NO local pollution

clean room compatibility, biomedical and food application

s

Benefits compared to sliding and rolling bearings

ZERO FRICTION

The total absence of friction is of very important in measuring systems, for example in coordinate-measuring machines, where air bearings are used to ensure perfect sliding movement of carriages, in order to avoid contact with the guides: the result is measures totally free from errors. No friction is a top priority in research laboratories, when primary (standard) measurements must be obtained for sectors related to LENGHTS, ANGLES, FORCES AND HARDNESS.

NO-CONTACT

The total absence of contact allows the motion systems to work 7/7 and 24/24 with high-dynamic cycles, ensuring both zero maintenance and allowing high production level. Therefore, maintenance costs are drastically reduced and ordinary maintenance can be properly planned.

GAS LUBRICATION

Dust or pollutants would affect the quality of production processes of electronic parts or biomedical devices. Therefore, gas lubrication technology – air bearing – is a key choice in clean rooms or in medical devices production.