PRODUCTION & PACKAGING OF FAST MOVING GOODS

MACHINES FOR PRODUCTION & PACKAGING OF FAST MOVING GOODS REQUIRES HIGHEST RESULTS:

- no wear of motion parts implying no maintenance and no plant downtime

- high flexibility programmability of the motion profile in the electrical axis

-

increased productivity

Our VALUE PROPOSITION applied to PRODUCTION & PACKAGING OF FAST MOVING GOODS

PRODUCTION &PACKAGING FOR FAST MOVING GOODS

requires attention to

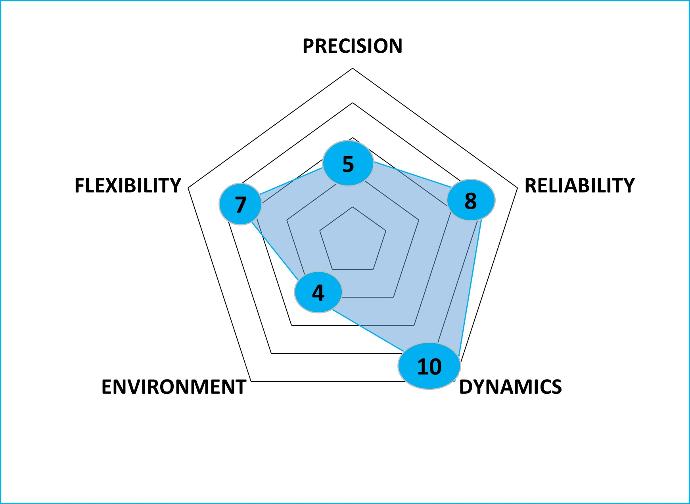

DYNAMICS,

RELIABILITY and FLEXIBILITY

- Dynamics is the most important feature to satisfy

- Reliability is the second significant task to reach

- Flexibility is a noteworhty requirement to take into consideration

Mager value proposition gives TOP PRIORITY to these TARGETS

Customers’ machines can benefits from air bearings motion solutions matched with direct drive motorization and reach higher dynamics performances which is a key point in this field.

Traditional motion systems based on rolling bearings and indirect drive suffer from high positioning rates, high accelerations, fast reverse motion and consequently they have drawbacks in terms of reliability: wear, damage of the motion systems which can also lead to collapse and thus plant downtime.

On the opposite, once again, solution is motion systems with air bearings technology.

The above listed benefits implies that the customer can get the perfect solution for machines involved in mass production of fast moving goods.